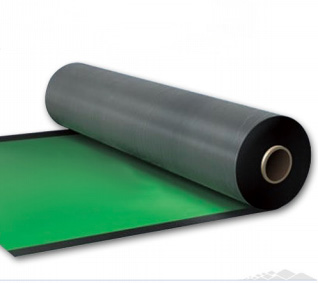

SELF-ADHESIVE WATERPROOF MEMBRANE

Advantage

● Anti puncture and impact resistance

● Staggered lamination forming

● Double layer or multiple cross pressure film

● UV resistance

● Tear resistance transmission

● Chemical corrosion resistance

● Low temperature resistance

Application scope

Used for non exposed roof and underground waterproofing projects, as well as waterproofing of open cut subway, tunnel, water tank, canal and other projects, especially suitable for projects where open flames are not allowed to be used; Cement mortar should be used to bond with the base layer, and self-adhesive overlap should be used between the rolls.

Construction points

· Clean the surface of the base layer thoroughly. The base layer can be damp, but there should be no open water. During wet paving construction, the dry base layer needs to be moistened with alcohol; When using the dry laying method for construction, the base treatment agent can be directly applied on the dry base layer.

· During the construction of flat waterproofing, it is required to conduct a trial laying of the rolls. The rolls should be laid flat in sequence and the longitudinal overlap width between the rolls should be 80mm and the transverse overlap width should be 100mm. After the rolls are laid neatly and the overlap is standardized, they should be sorted in sequence before proceeding to the next step.

· Use ordinary Portland cement not less than 42.5 and add an appropriate amount of water to form a slurry, with a water cement ratio of 0.4. Stir with an electric mixer for 1-2 minutes, mix well, and let stand for 5-8 minutes before use.

Use a scraper to evenly apply the mixed cement slurry onto the base layer. While applying the cement slurry, lay the waterproof membrane on the surface of the base layer and press it firmly with exhaust gas.

· Additional layers should be added to the node according to the specifications and design requirements. The additional layers can be made of self-adhesive rolls or double-sided self-adhesive tape. The ends and joints of the rolls should be sealed with matching sealing coatings.

Note

1. During the construction of the dry paving method, the base layer is required to be flat and dry, and a specialized base layer treatment agent is used for the base layer treatment.

2. When the wet paving method is used for construction, the air in the coiled material shall be driven out, and the coiled material and cement gel shall be fully adhered by pressing. The waterproof layer of coiled material after construction shall not be trampled. After the acceptance of the waterproof layer of the roll material, it should be protected as soon as possible to prevent exposure and physical damage.

3. For damaged areas, the surface of the damaged area must be cleaned thoroughly, and then repaired with self-adhesive rolls, with a minimum overlap width of 100 millimeters with the surrounding area.